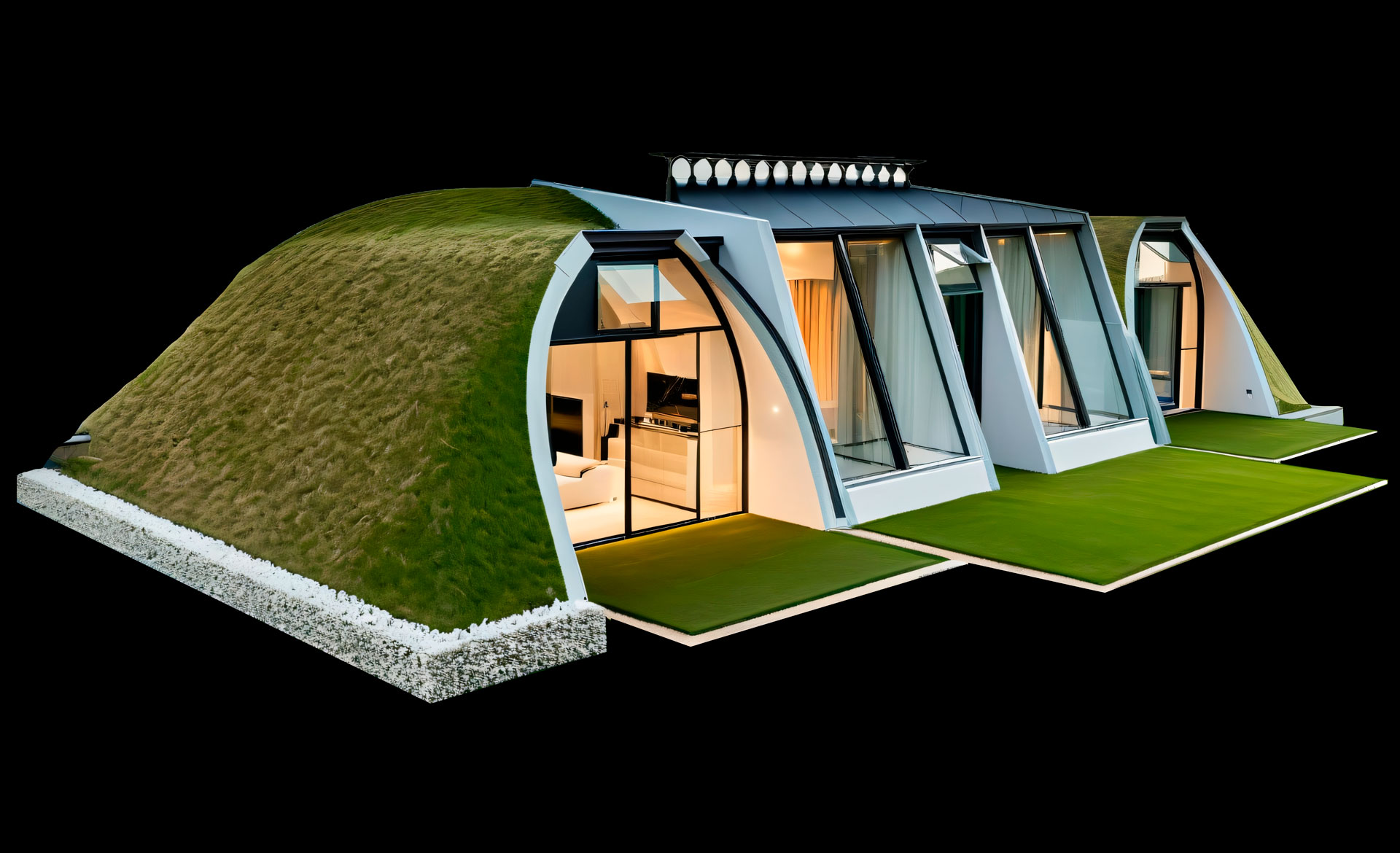

What is an OasisBioHome?

An OasisBioHome is a self-sustaining home designed to function independently of traditional urban utilities, commonly known as “off the grid.” It harnesses natural resources to meet essential needs. Our OasisBioHomes are constructed using next-generation Fiber Reinforced Polymers and locally sourced materials, and their design reduces the need for external inputs, resulting in substantial economic savings. These homes can generate their own resources, enabling residents to live without dependence on external infrastructure.

SAVINGS AND TECHNOLOGIES

FREQUENTLY ASKED QUESTIONS

Welcome to the FAQ page for OasisBioHomes by Wonderful Structures technology. Here, we address some common questions regarding our technology. We hope these answers enhance your understanding of our OasisBioHomes and its advantages. If you have any further questions or need additional information, please feel free to reach out to us.

Our technology features an innovative construction system designed to meet various standards for earthquake resistance, wind loads, and fire safety, making it eligible for approval worldwide. We recommend consulting your local building department to understand the specific requirements in your area. Additionally, standard construction permits will be needed for your project.

Yes, the finished modules from Wonderful Structures can be painted, though some types of paint may need a primer.

Yes, the interior walls are full-height, just like those in any standard home. We do not supply the interior walls; they will be constructed by a certified builder.

Yes, they can. For cold weather, our specifications involve adding an extra thick layer of closed-cell insulating foam, which is then topped with a broad layer of soil, grass, and plants. Snow load requirements will need to be assessed by our engineering team.

How do technical installations like plumbing, electrical, and sewage integrate with this technology?

Some technical pipeline connections are integrated into the slab foundation, like any standard home. Most of the connections are external. We provide detailed plans of the technical installations that are connected through the walls of the structure.

Yes, they can be installed easily. Overall, air conditioning and heating systems work exceptionally well within the Wonderful Structures system because of its thermal properties.

Yes, the ventilation system is tailored to each unit and will differ based on the construction site. Effective ventilation design is essential for maximizing energy efficiency. Typically, homes will employ either Energy Recovery Ventilation (ERV) or Heat Recovery Ventilation (HRV) systems.

The force needed to crack a module in the Wonderful Structures system is substantial and unlikely to occur by accident, as it would require a significant impact from a steel cutting tool or a similar object. However, if a crack does happen, repairing it is relatively straightforward and can be done using materials available at hardware or construction supply stores.

The R-value of the Wonderful Structures system depends on the type of thermal material utilized in its construction.

Our materials meet the ASTM E-84 standards as required by international construction codes. This compliance involves applying an intumescent coating to the panels during the manufacturing process. Documentation verifying fire compliance can be obtained

from our project managers and certified builders.

No, gas emissions are only produced during the manufacturing of components in our facility. Once the FRP is cured, the panels become completely inert and stop emitting gases, making them safe for long-term residential use.

The panels are sealed to the foundation using polymers, and Wonderful Structures outlines the steps to ensure that there is no water infiltration.

To bury a structure in a hillside, retaining walls must be constructed to support the earth pressure exerted on the structure.

It is essential to consult a geotechnical engineer to design the retaining walls and assess the soil conditions before proceeding with the foundation of the Wonderful Structures system.

* Such constructions must be evaluated by our architectural and engineering team.

A depth of 4 to 6 inches is sufficient for healthy vegetation to thrive.

The type of vegetation chosen depends on the local climate conditions where the structure is located. Using native plants can often lead to minimal or even zero maintenance. It’s important to note that when you build an earth-sheltered home, the surface soil will eventually return to its natural state. You can choose to enhance or modify this with improved soil, irrigation systems, ornamental plants, or other feasible options for your area. Low-maintenance ground-cover plants are a great option. We provide detailed information on compatible and easy-to-maintain plants for rooftop gardens based on your geographical location.

Wonderful Structures has developed a unique procedure tailored to our technology. The roof covering process includes waterproofing, thermal insulation, and sealing the joints between the modules that make up the home. The construction procedure will be thoroughly explained in our training sessions.

Financing options are available through banks, investors, and other sources.

At present, Wonderful Structures does not provide direct financing.

When you purchase from Wonderful Structures, you are buying directly from the factory. The Blake family has been in the manufacturing business for over 30 years, allowing them to offer custom composites at the most competitive prices.

Credit unions are often willing to offer loans for projects being constructed within their community.

No, Wonderful Structures provides only the construction systems and the required architectural drawings. A certified builder will handle the foundation and unit construction.

The package contains FRP shell components, galvanized nuts, washers, bolts, and expansion bolts. Additionally, the building dossier provides structural documentation, material properties, fire code compliance, waterproofing test reports, and engineering details for the technology.

We supply the main entrance door for the BioHomes and the three air extraction windows or vents that are located at the top of the facades. The doors are not included, as they can be purchased locally at favorable prices.

No, there is no minimum order requirement.

Yes, there is a 5-year warranty on Wonderful Structures components, but each certified builder offers their own warranty to clients, which may vary by country.

Wonderful Structures sells its products on an EXW (Ex-Works) basis. However, we can assist in organizing transportation through established cargo agencies.

No, your Engineer, Contractor, or Architect will be responsible for obtaining local permits, and Wonderful Structures will provide assistance during this process.

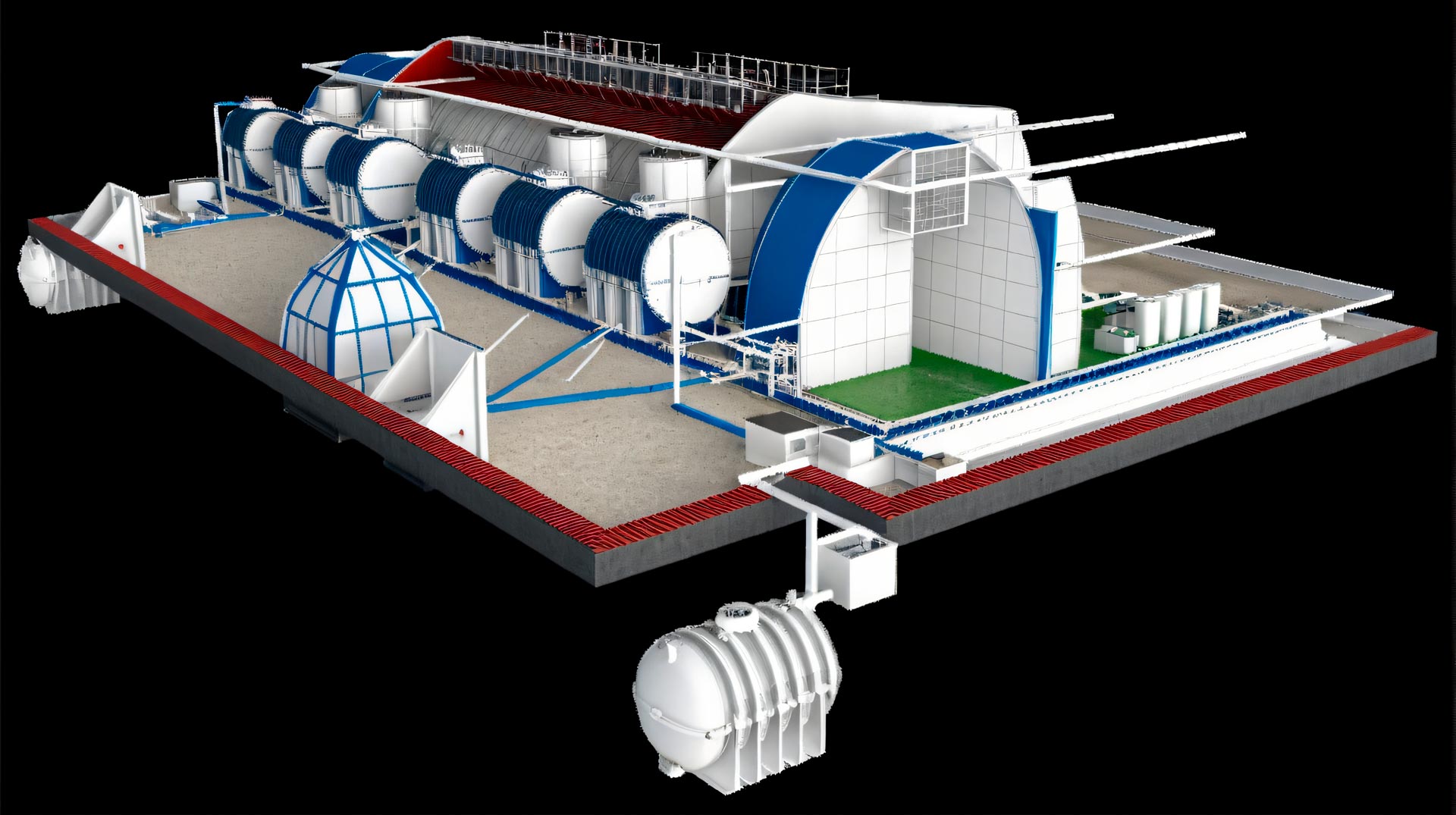

Yes, you can grow crops. To facilitate this, we have strategically designed 4 cultivation pools with gravity irrigation that filter recycled gray water in stages, allowing for the production of vegetables and greens 24/7, 365 days a year.

No, we manufacture the technology. Certified Builders, who are qualified professionals in your area, will assist with the construction of your Wonderful Structures.

The total cost of a complete unit varies based on the build location, additional material expenses, labor costs, and the builder’s expertise. Standard costs include the foundation, electrical and plumbing work, as well as interior finishes, exterior sealing, landscaping, and planting. For pricing on the technology, please fill out the contact form, and we will send you a Product Brochure and pricing information.

The prices do not cover foundation installation, adhesives, electrical and plumbing work, HVAC systems, exterior doors and windows, interior flooring, walls, cabinets, fixtures, appliances, water sealants, insulation, soil, garden coverings, and surface finishes. All images are for illustrative purposes only; furniture and interior/exterior finishes are not included.

The materials used in the modules are high-quality FRP, similar to those used in marine structures and industrial storage tanks. If the instructions in the technical installation manual are followed closely and all additional materials (sealants, fasteners, waterproofing, geo-textiles) are used as specified, you can expect a long lifespan with minimal maintenance. Over time, necessary maintenance or repairs will be minor and straightforward. The soil, grass, and plant coverage help protect the structure from UV rays and harsh weather conditions.

A 100 square meter (1,076 sq ft) home takes about 10 days to manufacture. However, the exact delivery time will be confirmed upon contract submission, as it depends on factors such as production queue and specific customer requirements for optional items. Typically, the entire process from payment of the retainer fee to delivery takes approximately 30 to 45 days.

Absolutely. Wonderful Structures are fully suitable for year-round living, just like any standard home or hospitality venue.

OUR TECHNOLOGIES ARE LINKED WITH

PRODUCT BROCHURE AND PRICES